STC designs and conducts sustainability learning journeys with MARS, Incorporated and other international corporations and simultaneously designs Integrated Bioenergy Facility in Riau Province, Sumatra

In January of 2013 STC Indonesia assisted the Sustainable Food Lab of Hartland Vermont in creating a Learning Journey for the sustainability team of one of the largest food companies in the world, Mars, Incorporated.

STC’s mission was to give the sustainability managers an experience within the supply chains of palm oil, rice and coconut that would deepen their understanding and stimulate new thinking on how they could impact these supply chains in positive ways. The participants had a chance to study the systems closely and to engage in dialogue with various stakeholders who were part of the system or had important perspectives on it. For this 8 day experience STC Indonesia arranged for the sites to visit and the stakeholders to speak to who could offer the most insight into the complexities of the supply chains and their social and environmental impacts.

The Learning Journey offered a way to see and experience aspects of the palm oil, rice and coconut supply chains that are complex and not easily understood. The goal was to help participants “see” the supply chains through new eyes through dialogues with their colleagues during the journey as well as through visits to various stakeholders.

—

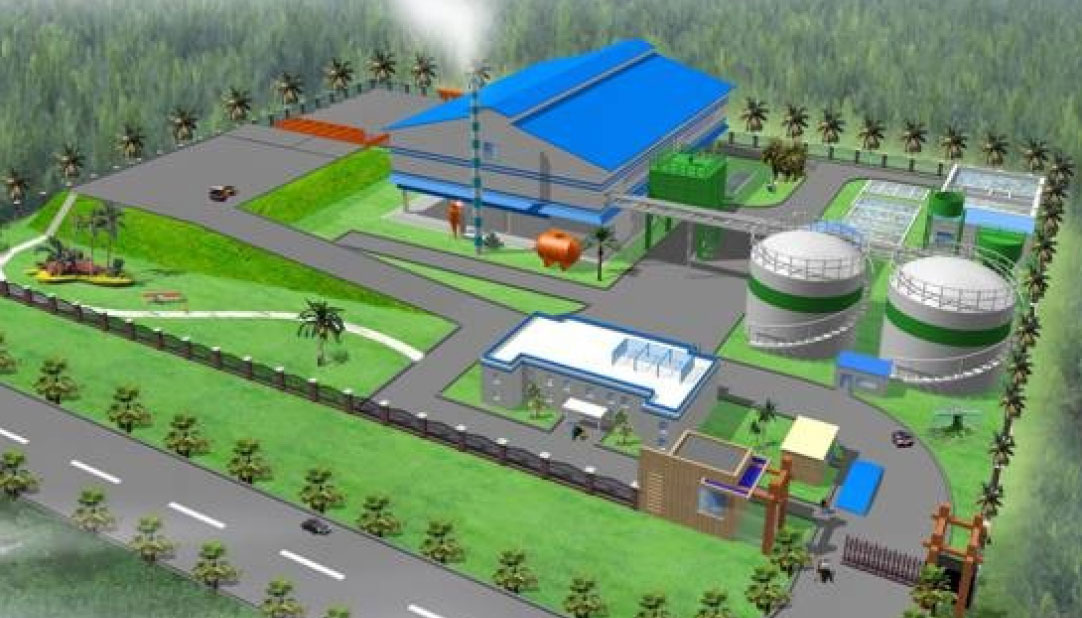

Also in 2013, STC developed an integrated model for a facility that can utilize multiple waste streams, plantation biomass from senescent oil palm trees, non-food grade waste fruits, waste oils from processing mills, and biogas from palm oil mill effluent (POME), for energy production in Kabupaten Siak, Province of Riau (Sumatra). This project was sponsored by Energy and Environment Partnership of Indonesia, an initiative from the Ministry of Foreign Affairs, Finland.

Unlike single-stream facilities, this integrated model enhances synergies by using solid, liquid, and gaseous feedstocks to produce heat, electricity, and other biomass products. The facility can produce over 10MW of green power for direct sale to PLN while generating a planned 90,000 carbon credits. The facility utilizes custom biogas reactors and pond covers with internal paddle-wheels to maximize biogas production and capture from POME. To further reduce COD and BOD levels before effluent is released for land applications, algae are cultivated in open pond systems.

For energy production, solid plantation biomass is pre-treated with heat recovered from the biogas combustion before being converted with cutting edge gasification technology. Excess supplies of non-food grade oil palm fruits and waste oils from the production facilities are used for the production of PowerOil, a low cost alternative to traditional fossil fuel, diesel, and pure refined vegetable oil.

Finally, to ensure that the biomass supply chains are reliable and sustainable, the application of GIS technology is integrated with an interactive Google Earth tool to monitor land use change, calculate GHG emissions savings, and optimize feedstock flows.

The project consortium consists of Maris Projects BV, a Dutch company specializing in POME biogas capture and bioremediation with microalgae production; PT Forest Carbon, an Indonesian GIS company committed to forest conservation; Indonesia Clean Power Ventures, an Australian bioenergy business incubator; and Perkumpulan Elang, an NGO in Riau focussed on resource conservation and community development.